This simulation is done to create an aero-thermal digital twin of a datacenter using CFD. The details of datacenter are taken from [1]. The datacenter CAD model is shown in Fig. 1.

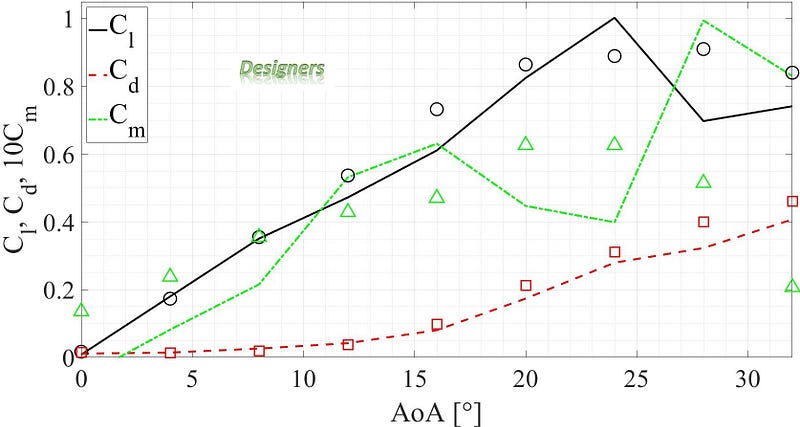

The simulation employs κ − ε turbulence model with damping functions, SIMPLE-R (modified), as the numerical algorithm and second-order upwind and central approximations as the spatial discretization schemes for the convective fluxes and diffusive terms. The time derivatives are approximated with an implicit first-order Euler scheme. Flow simulation solves the Navier–Stokes equations, which are formulations of mass, momentum, and energy conservation laws for fluid flows. To predict turbulent flows, the Favre-averaged Navier–Stokes equations are used.

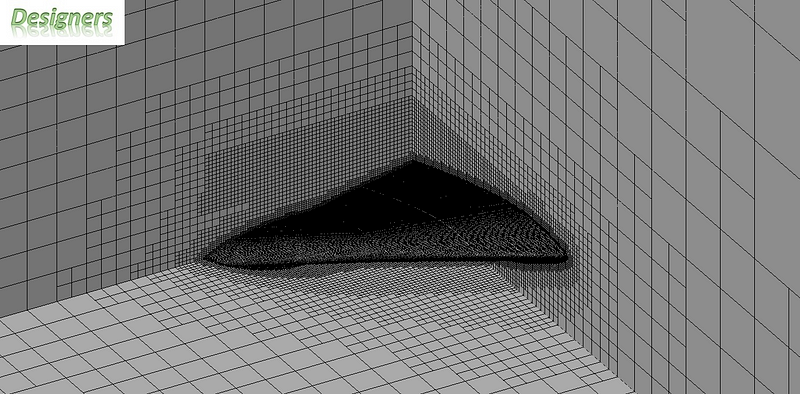

A Cartesian mesh with octree refinement, cut-cell method and immersed boundary methods is used. Special mesh refinements are deployed in the areas of interest i.e. inlets and outlets and sharp edges of server racks and CRAH units to accurately capture aero-thermal gradients and vortices. The resulting computational mesh has 2,698,156 cells. The computational domain and mesh are shown in Fig. 2.